BAF 2000

Benzol-Exhaust-Reduction

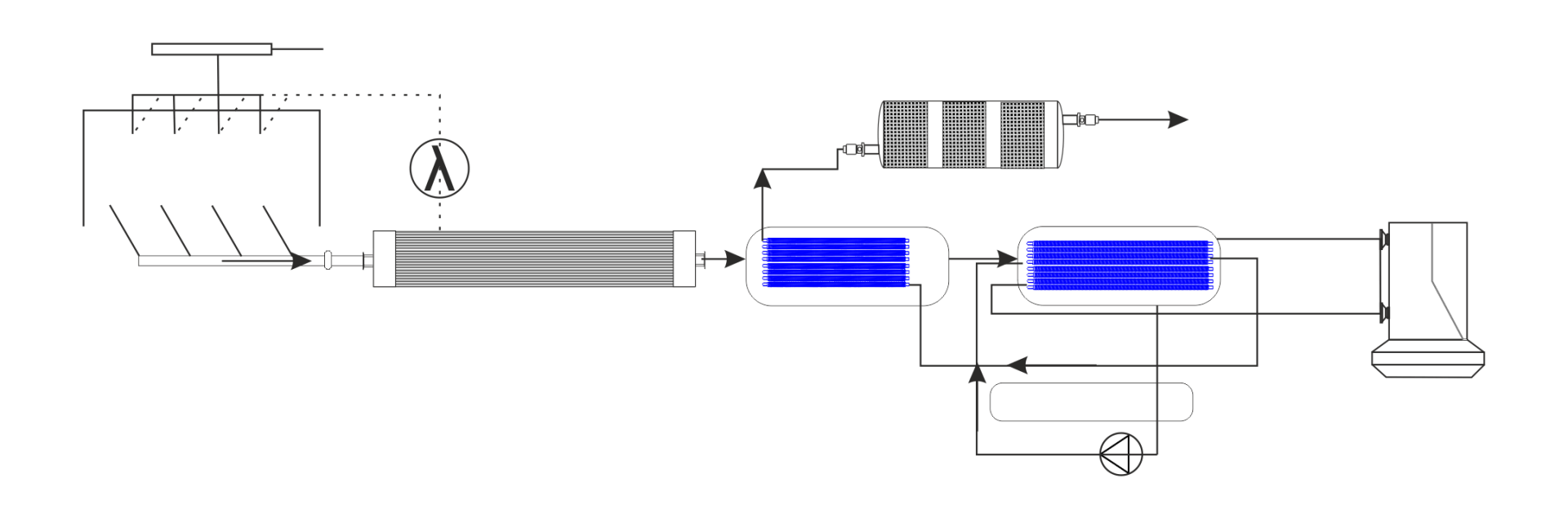

Method and device for reducing exhaust gas emissions and fine dust particles from internal combustion engines. Exhaust emissions from internal combustion engines are usually reduced by catalytic post-combustion of pollutants. In this process, catalytic converters are only used effectively under certain conditions. The new process is intended to achieve a further reduction in exhaust emissions in addition to the use of catalytic converters. The reduction of exhaust emissions is achieved by passing the exhaust gases (including nitrogen oxides) through a filter system, under pressure in one or more stages with rapid cooling. The rest of the exhaust gases are routed back to the combustion engines to be reprocessed.

Furthermore, main pollutants are separated (non-limited pollutants) such as:

· Total cyanide

· Total aldehydes

· Total phenols

· Differentiated hydrocarbons

· Polycyclic aromatic hydrocarbons

· Differentiated aldehydes and ketones

First introduction of the BAF on an exhibition in Germany in 1994

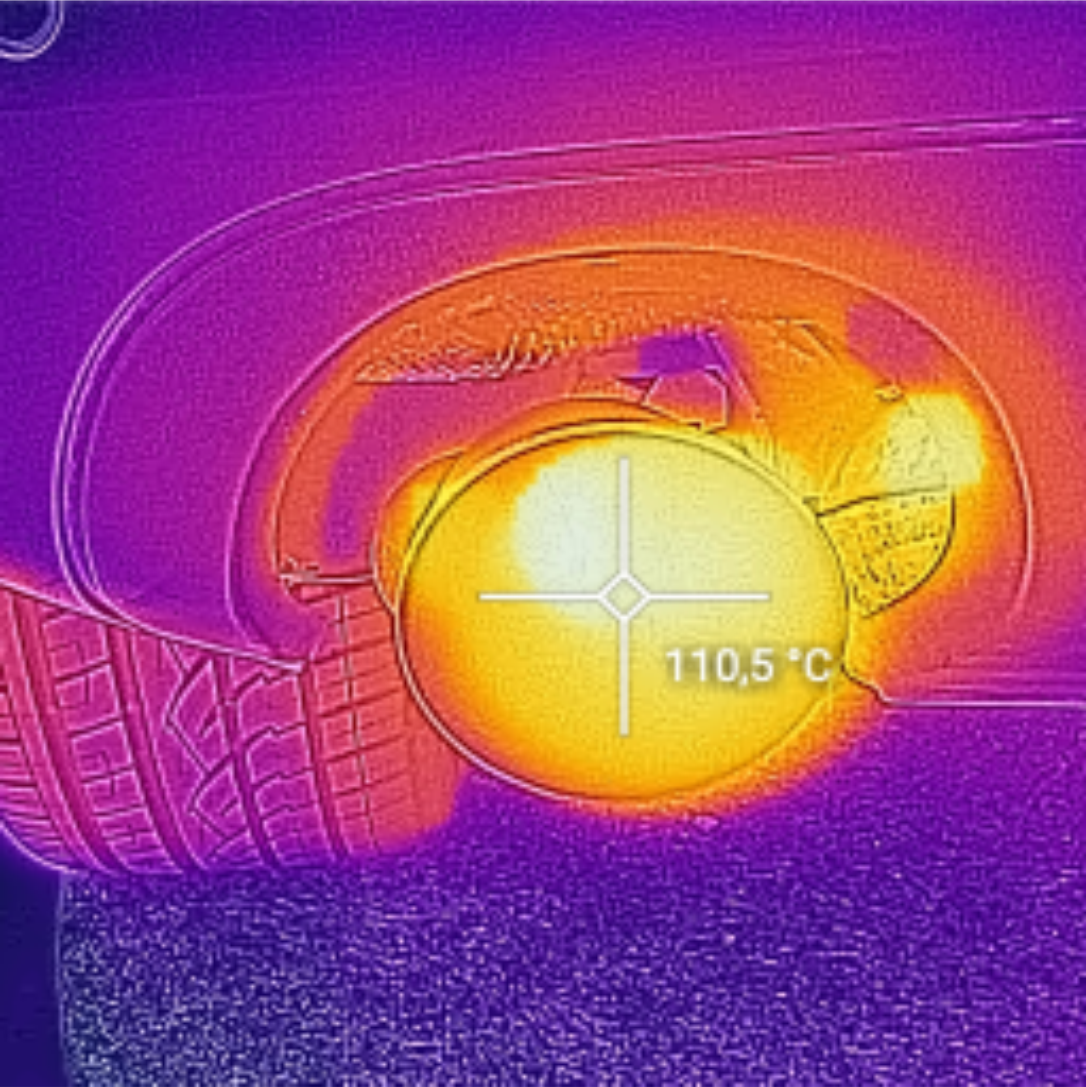

Pascal Stones are used to separate the non-limited pollutants. However, the excellent performance of the catalysts also forms new chemical compounds. Furthermore, the operation of the catalysts is only guaranteed from a temperature of 250°C (approx. 2-5 km driving distance).

This is taken into account in the BAF 2000 system. Altogether, the technology consists of two main stages.

The following values were recorded during exhaust emission measurements:

Carbon Monoxide CO reduced by 81.82% up to 100%

Hydrocarbon HC reduced by 53.85% up to 85.9%

Carbon Dioxide CO2 reduced by 62.38% up to 70.55%

Furthermore, test trials have proven that changes have caused that the following oxygen O₂ values were measured in the exhaust gas values when using BAF 2000 technology:

Increase of Oxygen O2: before 0.02% Vol. increased to 13.03% Vol. up to 15.15% Vol.

A phenomenon,

- was CO2 split into Carbon and Oxygen?