Blue Building® Products

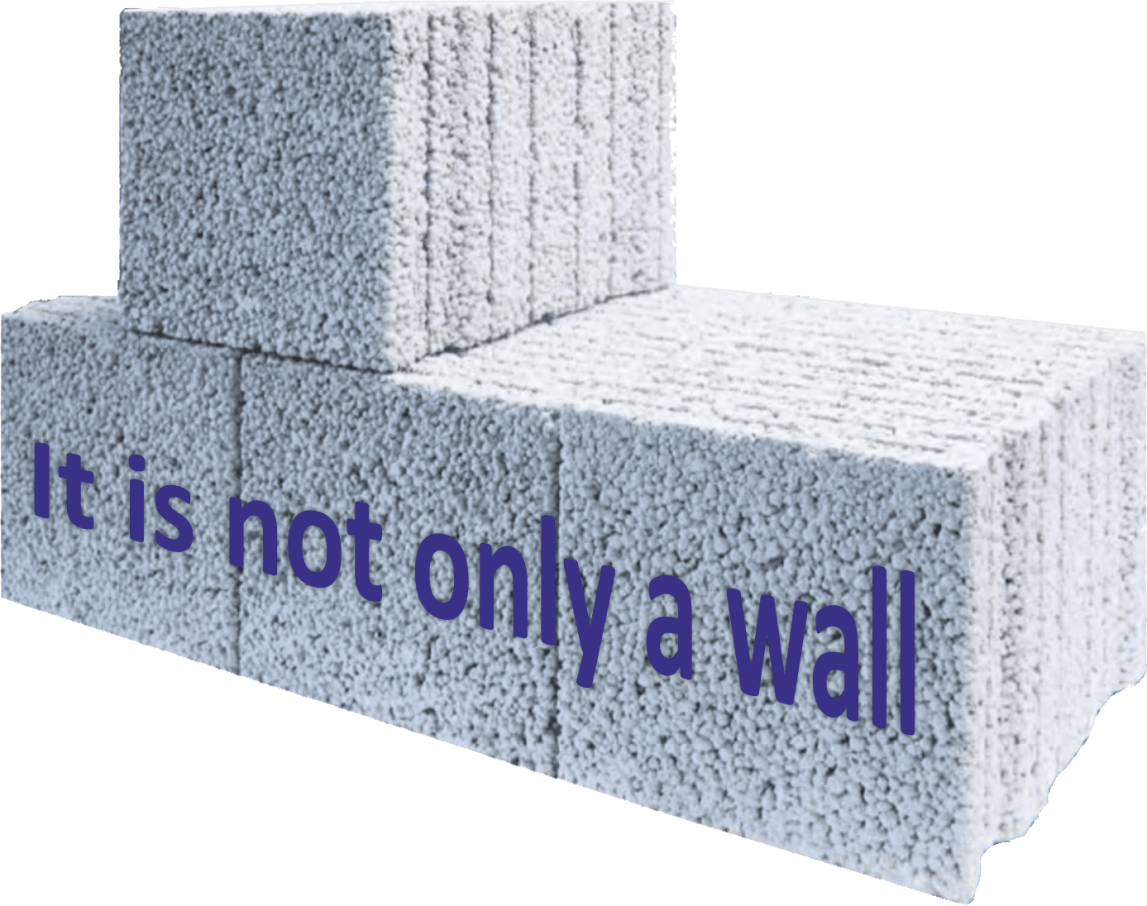

The Blue Block System

is based on advanced prefabrication techniques that allow the client to build a tailor-made shell construction in less than a week. By using factory-cut bricks made of lightweight, environmentally friendly Pascal Stones, a flawless result is achieved. The system consists of a double-wall filled with Pascal Stones that achieves an astonishing U-value of 0.09 w/m²K.

An innovative piping system

will be integrated in the ceilings. A central and efficient heat pump will provide cold and hot water, saving up to 80% energy.

The Cooling-Heating Ceiling

With the Cooling-Heating Ceiling, Blue Building offers an intelligent and sophisticated system, which keeps both building costs and energy usage to a minimum. The Cooling-Heating Ceiling effectively cools resp. heats the room without developing drafts or creating noise that exists with conventional air-conditioning units.

Superior Insulation

Design; economic efficiency; thermal insulation; conductivity of Ug 0.69; sound insulation; security; environmental protection.

Controlled Air Circulation

Good indoor air quality is subject to many factors.

The Blue Building stationary controlled air circulation system installed in the building was not only able to remove bacteria and pollen from the air. In addition, it also eliminated most viruses (99.995%). In addition, this system was able to reduce CO2 levels in the building by up to 47%; a result that is unique in the world.

No Legionella Formation

A healthy and comfortable water supply with our 850 l water tank and preventing the formation of legionella.

Technical Room

is the heart of every 'blue' building. It contains the technical equipment, heating & cooling system, controlled air circulation and warm and cold water supply.

Blue Blocks

Supplied by a trusted partner of Blue Building

Thermal protection pays off. It becomes increasingly important for architects, designers and builders to handle energy related design issues with great care. Requirements of construction physics for exterior walls have increased. Wall elements made of light weight concrete provide excellent thermal insulation criteria for both summer and winter temperatures.

Lightweight concrete offers the best performance in terms of sound insulation, sound absorption and sound absorption. Lightweight concrete is fireproof and certified as a fire-resistant building material. Blue Building wall elements can be installed as fire walls.

Blue Building houses are planned individually and tailor-made. From the planning stage until hand-over of keys, the Blue Building® system provides technical support to the architect, civil engineer and client, preventing potential sources of error. The system consists of the Blue Block System (wall), ceiling and roof elements, which are connected by a tongue and groove concept and can be adapted to current needs. These elements are calculated with CAD software and then prefabricated.

The building technologies used were developed specifically for the Blue Building® Concept. Some developments (for example the Pascal Stone thermal insulation) have taken 25 years and are also used in other Blue Building® innovations. The concept of Blue Building® construction dates back in part to ancient times. Experience from other low-energy house standards, especially the German standard, has also been incorporated. The Blue Building® houses meet and exceed the requirements of the German passive house. The extraordinary ease of transport and assembly further distinguishes the Blue Building® system from competing prefabricated building systems.

Blue Building® elements come with an integrated cooling and heating system, air conditioning, thermal and sound insulation as well as fire and corrosion protection. Additional wall covers are unnecessary. All technologies shown are proven systems by European DIN and are operating successfully in Germany and worldwide.

Construction:

Short construction time; Completion of the shell construction after 6 days thanks to the Blue Block System, handover of keys after 45 days

Architecture:

Feel-well effect through harmonious construction; Avoidance of the Sick Building Syndrome

Healthy:

Indoor climate through low-impact air movement, humidity control, dust and bacteria filter; energy saving; natural and artificial light sources, low heat output, reduction of electric smog; dust filtering; biological filter; supply of healthy drinking water

The wall:

Extremely good insulation, for example in the United Arab Emirates a U-value of 0.09 w/m²K was achieved, with particularly hot outside temperatures in summer:

Surface temperature inside: 20.6° C

Surface temperature outside: 54.8° C

For people it is best to live in their own house. Recent studies show that living in upper floors, especially in high-rise buildings, is not good for the well-being. The energy is partially split and cannot flow. The person begins to feel tired or under pressure. Contact with the earth and the cosmos is particularly important, as is the use of the Blue Building Concept.

Today, these problems are summarized under the term “Sick-Building-Syndrome”.

Constructing according to the Blue Building Concept, governments will save huge amounts in the public health care system, as well in saving energy. The difference of energy consumption between ordinary concrete (80,000 kW) and the Blue Building System (1,800 kW) is for the same villa 78,200 kW per year.

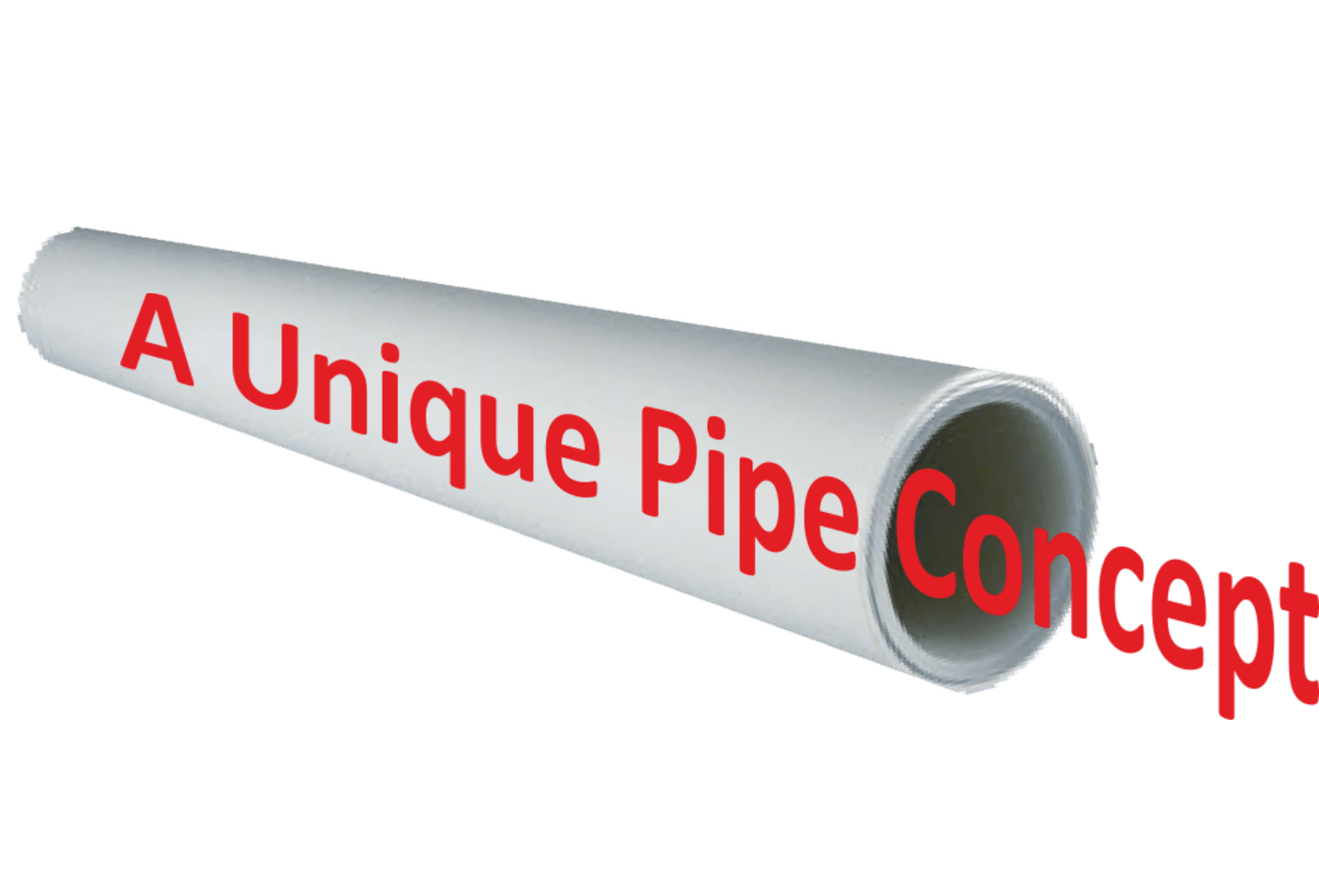

Blue Building Piping Systems

Supplied by a trusted partner of Blue Building

New roads in Climate Techniques

Advantages of capillary tube mats

For temperature regulation, water capillary vessels have succeeded; for example in the leaves of plants or beneath the human skin. Water will conduct heat 1000 times faster - it is much more effective.

Capillary tube systems use this evolutionary technology for the regulation of room climate with best results.

Multi-Layer Pipes

Multilayer pipes combine all the advantages of a modern material: in full balance between maximum operating performance and environmental compatibility through the economical use of resources. The pipe offers a high load-bearing capacity for daily use. The pipes consist of 5 layers, PE-RT, adhesive, aluminium, adhesive, PE-RT.

Advantages of metal and plastic pipes

Due to the welded aluminium pipe, the pipes are absolutely oxygen-tight and have minimal thermal linear expansion. Due to the smooth inner wall, no deposits can clog the pipes. They are up to 70% lighter than metal pipes and due to the high chemical resistance no corrosion can occur.

The Blue Building Efficiency: Cooling - and Heating Ceilings

A trusted partner of Blue Building

With the Cooling-Heating Ceiling, Blue Building offers an intelligent and sophisticated system, which keeps both building costs and energy usage to a minimum. The Cooling-Heating Ceiling effectively cools resp. heats the room without developing drafts or creating noise that exists with conventional air-conditioning units.

The technology is based on a piping system which is cast into the ceiling according to the ceiling plan. In operation together with a reversible heat pump, the system can also be used for extensive air conditioning in the summer. Cold water flows through the piping system in the ceiling to absorb excess heat from the air in the room, reducing the temperature of the ambient air.

Every ceiling element is individually manufactured according to plan. A fully cast piping system covering the entire surface of the ceiling is what makes our ceiling such a highly efficient heating and cooling system.

This system is adjustable. A central and cost efficient chilling unit will provide cold water, saving up to 80 % energy.

The climate control is based on water as a medium instead of treaded air. Blue Building provides a healthy and comfortable living environment without all problems regarding to hygiene touch as fungus, allergies and draughts.

For a good indoor climate, thermal ceiling radiation and air temperature interact to produce data that scientists call operative room temperature. To feel comfortable, thermoreception must not exceed values of 23°C. Due to the use of conventional air conditioning systems, the indoor air temperature of many buildings in warm regions is very low (sometimes below 20°C); but due to the use of walls with high U-values (mostly concrete) of more than 2 to 4.0 W/(m2K), the surface temperature in the interior of the wall is 27 to 38°C. These data lead to an operative thermal perception of more than 25 to 31°C.

Normally, people feel uncomfortable at such a high indoor air temperature. With Blue Building, with an outdoor air temperature of about 50°C, the indoor air temperature can be adjusted individually without any problems. At temperatures around 24°C, the occupants feel much more comfortable.

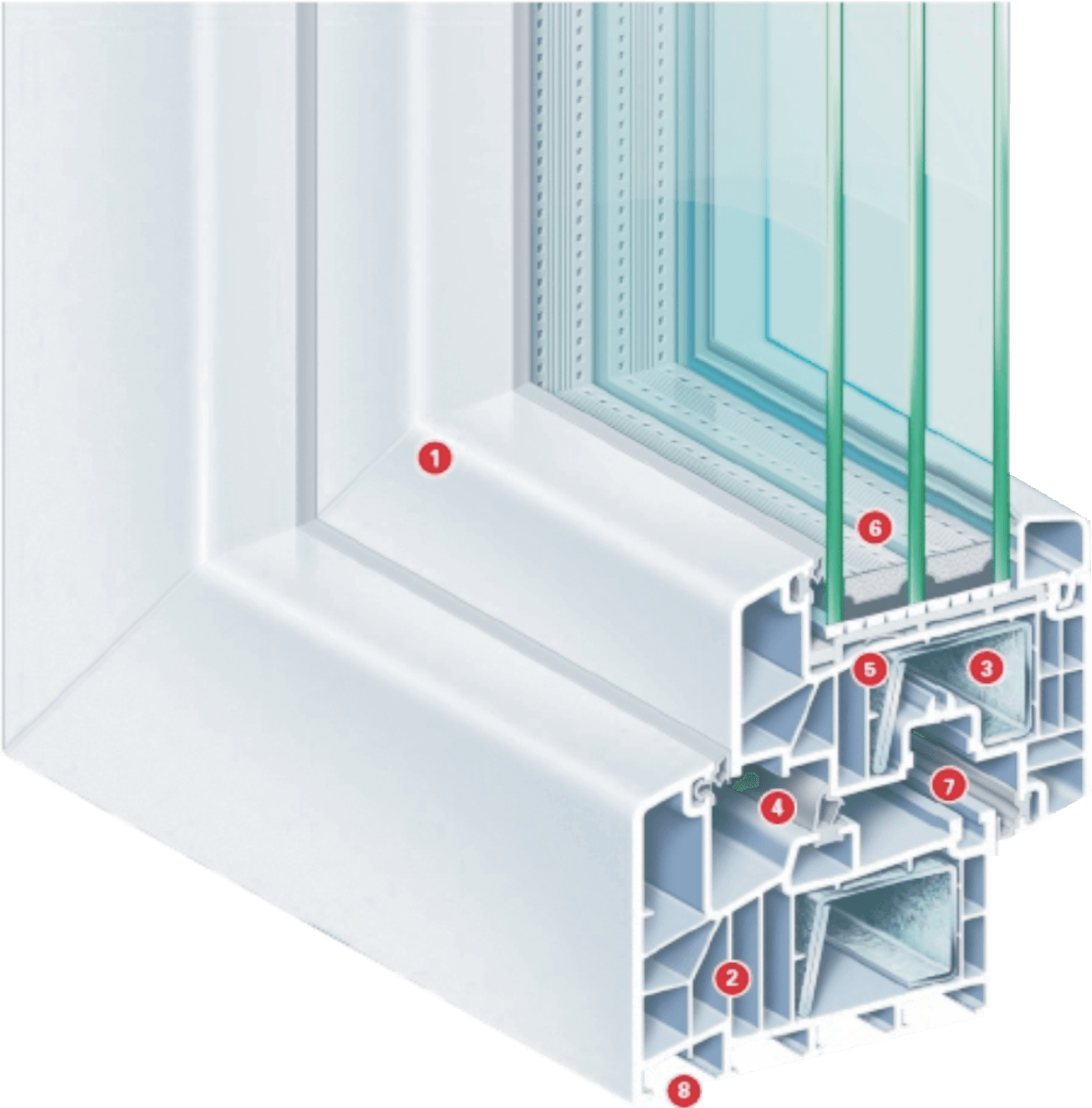

Blue Windows

Supplied by a trusted partner of Blue Building

More sound insulation or more thermal insulation? More design or more economic efficiency?

With old windows, you lose up to 40% of the room heat. Whether environmental awareness or saving on heating costs - the modern, energy-efficient windows and doors from Blue Building are the right decision in any case. With highly insulating frame constructions and thermal insulation glass, you can meet the requirements of the future today.

These combined requirements on modern new buildings or renovations have increased significantly over recent years. The window always plays a key role in this regard, because, as an especially sensitive part of the house, it contributes significantly to the buildings overall design, including energy consumption, sound insulation and security. We are setting new benchmarks – but not just with the high performance of our PVC-U windows. This new generation of profiles strikes just the balance between diverse technical requirements – between what is desirable, and what is feasible.

- Straight-lined recessed design with perfect profile proportions and slim profile aspects for maximum possible incidence of light and superior extraction of solar energy

- Highly insulated 6-chamber thermal centre sealing system with 88 mm construction depth

- By incorporating a specially formed steel reinforcement, the system is expanded by a further 7th chamber

- Triple level sealant system with a centrally arranged thermal middle seal further guarantees high resistance to driving rain, optimal imperviousness to wind and outstanding soundproofing

- The innovative casement rebate seal reduces thermally induced air movements in the casement rebate, which is why the thermal insulation values are so outstanding

- Wide range of glazing from 24 - 52 mm allowing the use of special functional glasses

- Upkeep very easy and maintenace low because fittings are located in the protected region beyond the thermal central seal.

- Reliable assembly due to perfectly prepared structural connections for inner / outer window sills and connecting profiles.

Blue Building Office in Sharjah, United Arab Emirates

Southside View

Outside Temperatures Wall 47.5°C

Outside Temperature Windows 45 - 50°C

Indoors Temperatures Wall 20°C

Indoors Temperature Windows 22 - 25°C

A Research and Development Project

Blue Glass / New

When constructing a low-energy building, the energy consumption due to the heat transfer of glass is a challenge. With a new technology, the Blue Building team has developed "Blue Glass", which has a unique Ug value of less than 0.1. Double glazing with high protection against intruders is an additional aspect.

The next steps of our efforts is to reach a new level of improvement in the building industry. The insulation value has always been a significant factor to achieve higher levels of environmental quality. Windows of high Ug-Value are one of the key factors.

The Ug-value for the future window glass has proven to be between 0 and 0.1

Controlled Air Circulation System

Blue Air Purification System

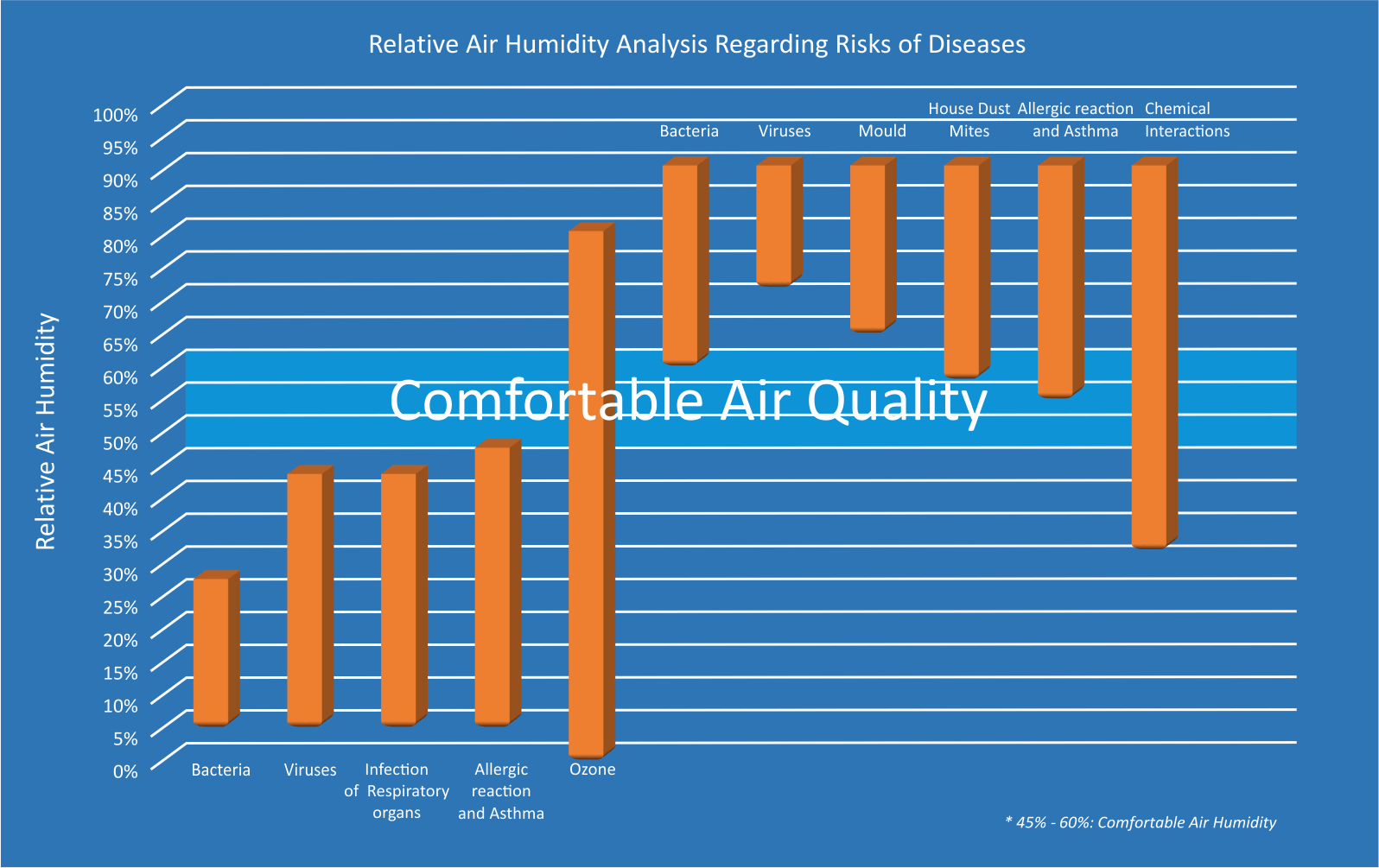

Good indoor air quality is subject to many factors. These are determined by the following conditions, among others:

1. CO2 pollution

2. Dust particle pollution

3. Relative humidity

4. VOC values (volatile organic compounds)

Regrettably, there are many different scientific statements regarding CO2 pollution in the air. According to Max von Pettenkofer, the limit for poor indoor air quality is 1000 ppm. According to the SIA guideline 382/1, indoor air is defined as being of good quality if it is between 800 ppm and 1500 ppm.

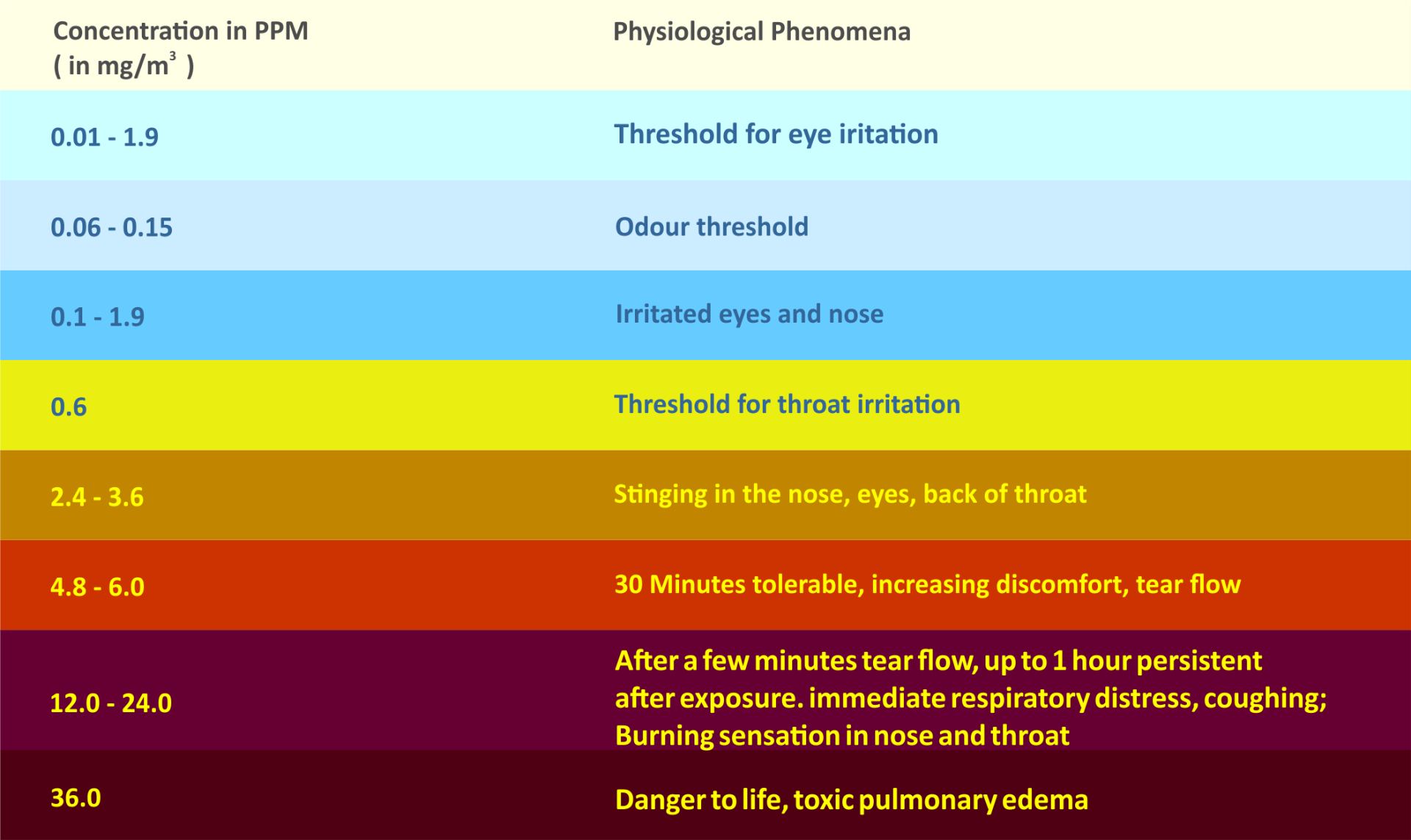

HCHO (Formaldehyde) Table

Values above 1500 ppm are problematic from health aspects. Healthy indoor air increases the performance of a person in buildings by about 25%.

Poor indoor air has an effect on the body's immunity.

Observations and scientific evaluations clearly show that more people die from poor indoor air than from poor outdoor air.

The Blue Air Purification System is a stationary system that can eliminate or filter harmful fine dust, bacteria, viruses and pollen without great effort. It ensures a healthy and comfortable indoor climate and guarantees the occupants a hygienic, mould-free, allergy-friendly and draught-free exchange of fresh air. The air humidity is regulated to approx. 50-60 % and offers ideal conditions for the well-being of all residents. Allergy and disease-causing particles are filtered out or eliminated. An increased rate of air exchange can be set for family gatherings without causing draughts. The windows can remain closed, which leads to a significant reduction in energy costs. At the same time, security and comfort are improved.

The stationary Blue Air Purification System has run from 2014-2020 (until relocation to Scotland) in the Blue Building office in Sharjah without any problems. When this laboratory and office was built in 2014, no one expected the following result: the stationary controlled air circulation system installed in the building was not only able to remove bacteria and pollen from the air. In addition, it also eliminated most viruses (99.995%). In addition, this system was able to reduce CO2 levels in the building by up to 47%; a result that is unique in the world. Values of 221 ppm carbon dioxide were measured on average, while outdoors in Sharjah values of 415 ppm carbon dioxide were measured on that day. From 2014 to 2020, air quality measurements were taken around the clock; the lowest CO2 level achieved indoors was 219 ppm carbon dioxide.

A high CO2 concentration indoors is very harmful to human health; this value should always be controlled. The Blue Building BAPS takes into account physical conditions that have other positive aspects besides reducing CO2 levels. BAPS systems are necessary for offices, conference rooms, shopping centres or even large shopping streets where no natural greenery is used for air filtration. The human body needs oxygen; a CO2 content of less than 1000 ppm leads to an increase in human performance of up to 30%.

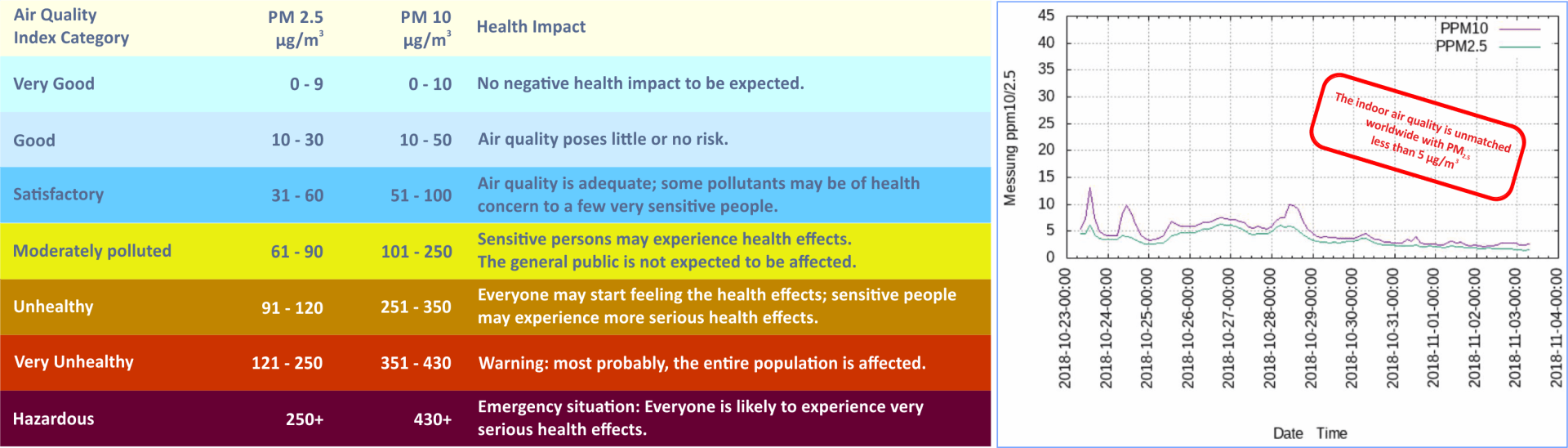

PM2.5 and PM10

The numbers 10 and 2.5 refer to the µm diameter of the particulate matter. Particulate matter is microscopic solid or liquid matter floating in the Earth's atmosphere. They include: gases, smoke, smog, ash and dust, viruses and bacteria, allergens, mould spores and pollen.

Particulates are the deadliest form of air pollution due to their ability to penetrate deep into the lungs and blood streams unfiltered, causing permanent DNA mutations, heart attacks, and premature death. In 2013, the ESCAPE study, which involved 312,944 people in nine European countries, found that there is no research on particulate matter per m3, except that for every 10μg/m3 increase of PM10, the lung cancer rate increased by 22%.

Some particulates occur naturally, originating from volcanoes, dust storms, forest and grassland fires, living vegetation, and sea spray. Human activities, such as the burning of fossil fuels in vehicles, power plants and various industrial processes, also generate significant amounts of particulates.

The Health Impacts of PM2.5 and PM10μg/m3 at various Air Quality Index Categories

According to a study in 2018 from the Max Planck Institute (MPI), particulate matter causes more deaths that hitherto assumed and the study talks about approximately 120,000 premature deaths caused by particulate pollution in Germany alone.

Experts assume a death rate of more than 30 million people worldwide due to air pollution.

TVOC

When solvents and chemicals in liquid or pasty products (household cleaning products, cosmetics, perfume, paints, etc.) evaporate, VOCs escape in large quantities into the ambient air. Added to this are materials from poor quality construction or interior design that contain plasticizers, solvents, stabilizers, etc. These are constantly released and lead to the well-known sick building syndrome. The use and evaporation of the above-mentioned agents also produces a not inconsiderable amount of fine dust. Initial studies have shown that this fine dust pollution is higher than the emissions from the automotive sector.

CO2 Levels

CO2 levels indoors have been measured between 219 and 800. New studies show that even the substance of CO2 in the typical room concentrations above 1.000 ppm can lead to a decrease in performance. It is therefore an indicator of indoor air quality in general.

CO2 Concentration at the

Blue Building Office in Sharjah

on 24.08.2014 at 6:12am on 11.05.2019 at 7:02am

At the same time, CO2 levels of 414 ppm were measured outside.

At a CO2 concentration of more than 5,000ppm, nausea and increased heart rate occur. A CO2 concentration of 6,000ppm is hazardous to health, so these exposures should only be short term.

At more than 10,000ppm, breathing difficulties and dizziness occur; at more than 30,000ppm, breathing frequency and breathing volume increase; at 40,000ppm loss of consciousness is possible.

At a CO2 exposure of 100,000ppm or more, candles extinguish, the person experiences nausea with vomiting and loss of consciousness. From a CO2 load of 200,000ppm, unconsciousness occurs quickly and leads to death.

When staying indoors, if there is no controlled air circulation or air purification system available, a continuous increase of increased pollutants can be observed. Necessary ventilation by opening windows in buildings is often not possible due to construction measures (closed windows in high-rise buildings or hotels) and in many countries due to climatic conditions.

There are no urgently required meaningful studies on ultra-fine dust pollution; existing studies contradict each other. These dusts are storage places for bacteria and germs, they penetrate via blood vessels to the brain. When the epidermis of humans is damaged by scratches, insect bites or allergy-related skin diseases, these pollutants can also penetrate directly through the skin into the body and thus into the bloodstream.

Studies carried out by professional associations show that cancers diseases have a death rate of up to 20% at people who have been exposed to high levels of dust.

A Research and Development Project

BAPS - The innovative mobile System

Together with their partner, Blue Building has initiated a revision of the controlled air circulation system and has incorporated a new cleaning system that will lead to the best cleaning results in the world.

Most importantly, the end user does not have to change any pollen or dust filter. With this system, 99.995% of dust and pollutants can be filtered out, which is extremely important for human health.

For more information on our Research and Development Projects,

please refer to our Blue Building Environmental Organisation Website

Around the World, the Pettenkofer Number

Source:

https://commons.wikimedia.org/wiki/File:Max_von_Pettenkofer.jpg

Max Joseph von Pettenkofer

Max Joseph Pettenkofer, ennobled in 1883 as Max Joseph von Pettenkofer (3 December 1818 – 10 February 1901) was a Bavarian chemist and hygienist. He is known for his work in practical hygiene, as an apostle of good water, fresh air and proper sewage disposal.

The greatest contamination of indoor air is caused by people themselves - Max von Pettenkofer was convinced of this. In his book 'Über den Luftwechsel von Wohngebäuden' (On the Air Exchange of Residential Buildings), published in 1858, he argued that air pollution can be significantly reduced through good cleaning of buildings.

Max von Pettenkofer indicated “bad air” as a negative influence after longer stays in living quarters and teaching institutions. He identified carbon dioxide as the most important leading component for the evaluation of indoor air quality.

Crowded rooms tend to be overheated and during this era it was considered that the discomfort in such rooms was due to excessive heat or, in accordance with the view of Lavoisier, due to elevated concentrations of CO2. Pettenkofer (1818 – 1901) started lecturing on hygienic topics in Munich 1847, and installed as the first professor in hygiene worldwide 1853 noted that the unpleasant sensations of stale air were not due merely to warmth or humidity or to CO2 or oxygen deficiency, but rather to the presence of trace quantities of organic material exhaled from the skin and lungs (Pettenkofer 1858). He stated that ‘bad’ indoor air per se did not make people sick, but that such air weakened the human resistance towards ‘jede art krankmachenden Agentien’, i.e., in modern words acted as an adjuvant factor.

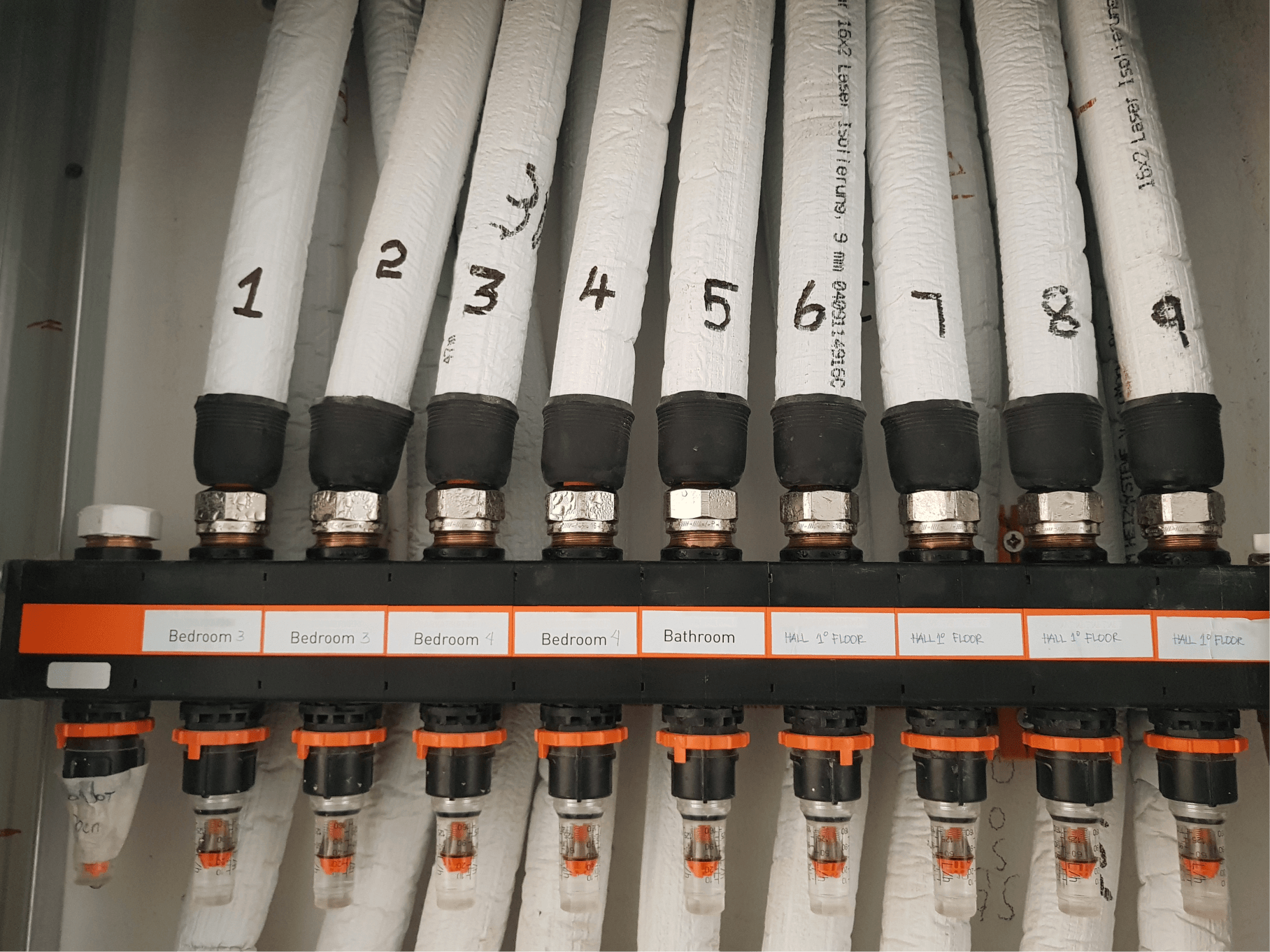

Hot and Cold Water Supply

Supplied by a trusted partner of Blue Building

Continuous hot water supply is ensured with a specially designed heat pump and perfectly sized water tanks. The water in a tank must be regularly heated to 60⁰C to prevent the accumulation of harmful bacteria such as legionella.

The hot water system in the Blue Building houses is designed that the water heats up to 70°C once a week (e.g. at the weekend, at night) to prevent legionella formation as effectively as possible.

With a built-in stainless steel heat exchanger, the water in the tank thus becomes a heat storage tank that is used to heat the water that flows through the heat exchanger and to the taps and radiators.

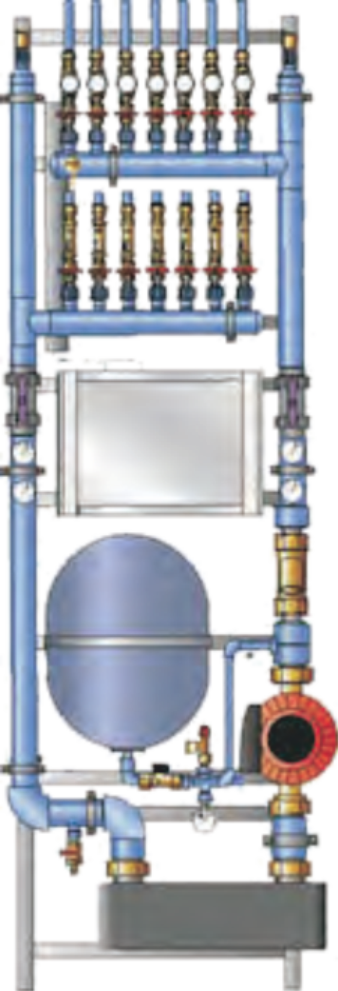

The Cooling & Heating System

With the Cooling and Heating System, Blue Building offers an intelligent and sophisticated system, which keeps both building costs and energy usage to a minimum. The integrated cooling and heating system effectively regulates the room temperature without creating draughts or noise as we know it from conventional air conditioners.

The technology is based on the piping system that is cast into the ceiling according to the ceiling plan. Cold or hot water flows through the piping system in the ceiling. When operated with a reversible heat pump, the system can be used for large-scale air conditioning in summer or for heating in the colder months of the year.

Every ceiling element is individually manufactured according to a plan. A fully cast piping system covering the entire surface of the ceiling is what makes our ceiling such a highly efficient heating and cooling system.

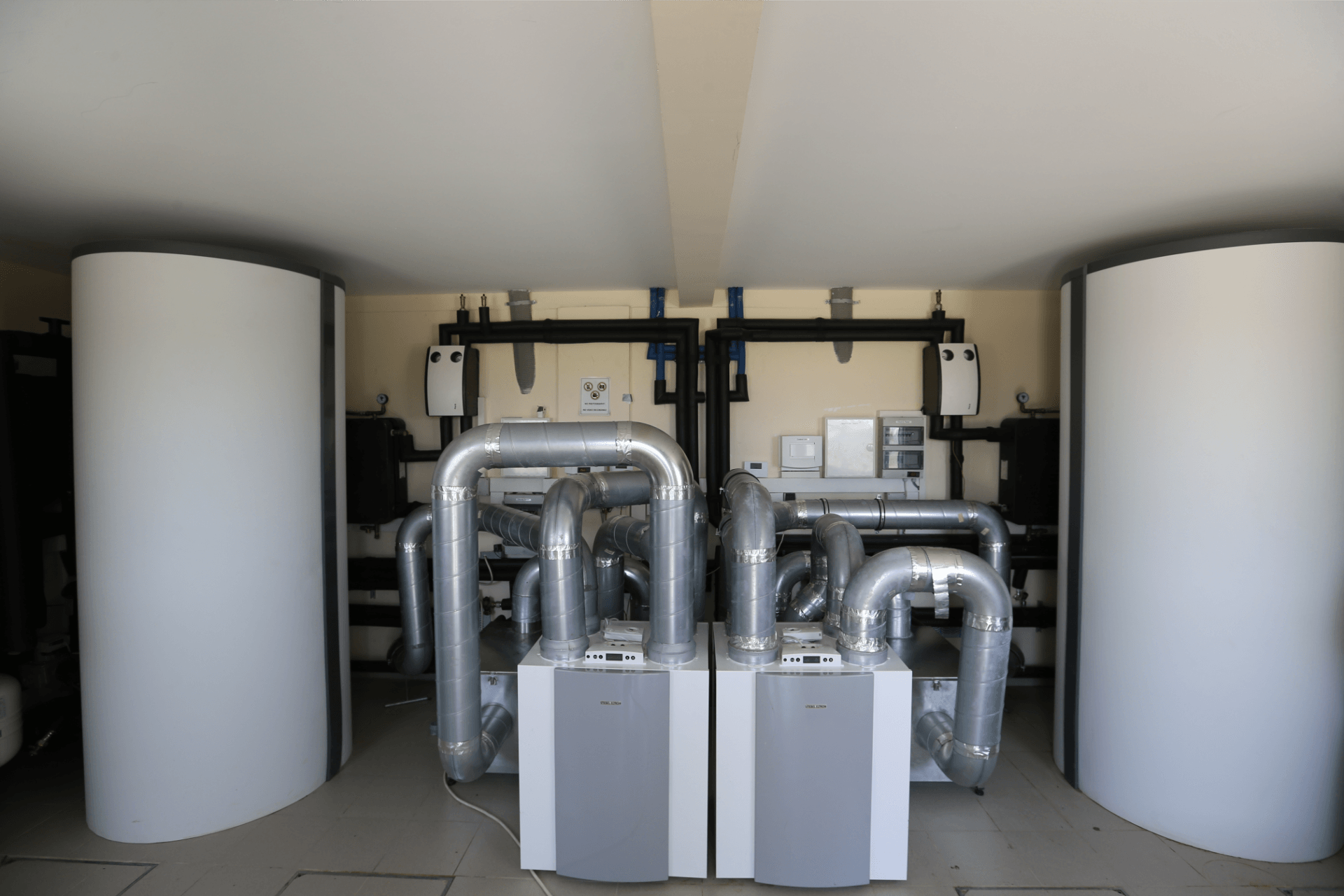

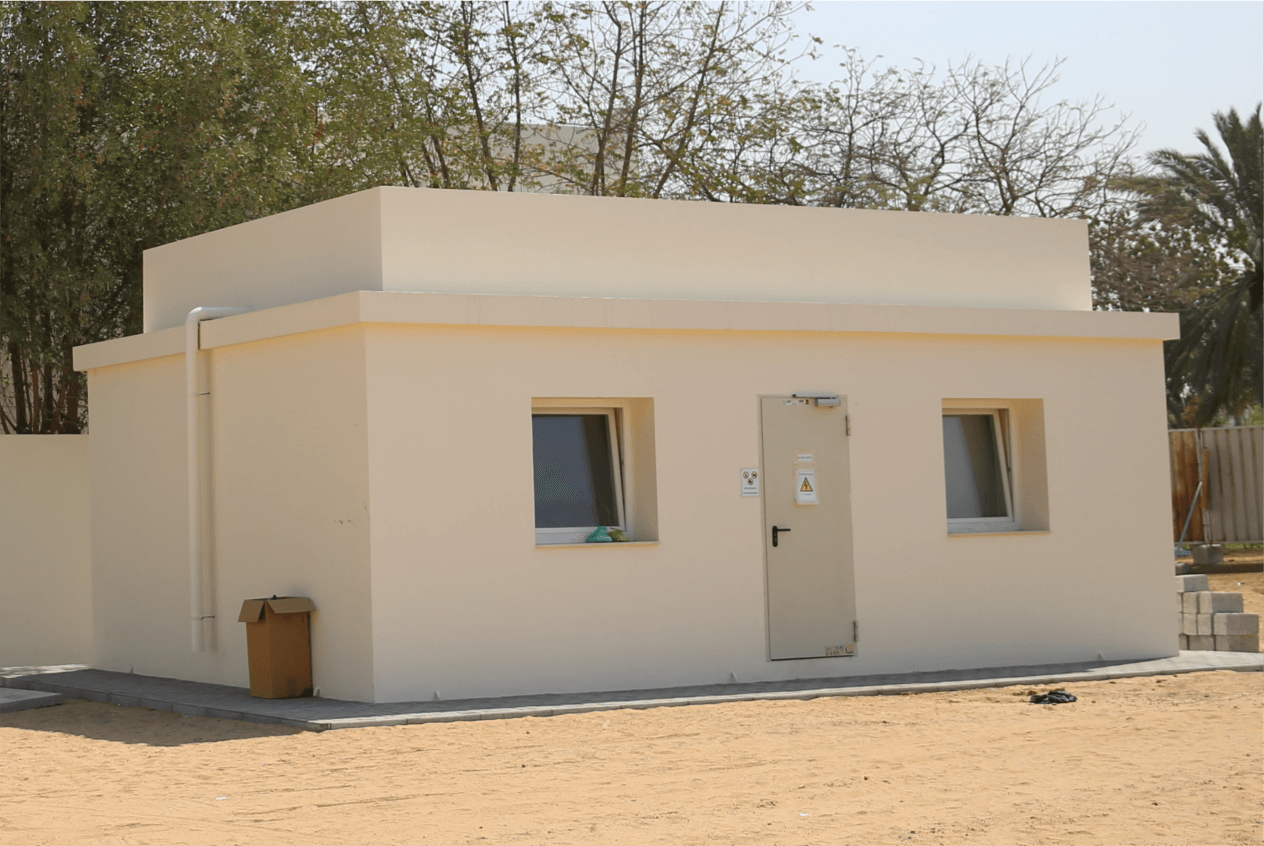

The Blue Building Technical Room

The Blue Building Technical Room is the actual ‘heart’ of the building. Whether placed inside the building, e.g. in the basement, or externally as a small building of its own, it contains the building’s technology. Interesting for new community areas: one external technical room can supply up to 4 single-family homes.

The cold/hot water supply for the cooling or heating system for the water taps, as well as for the ambient heating system, is located there. The built-in Blue Air Purification System is also installed there. The house is constantly supplied with fresh and purified air via a special pipe system, while used air is extracted - it is actually no longer necessary to open the windows to let in fresh air.

The indoor climate settings can be adjusted individually by the residents. Therefore, each room has its own control system. The system itself is externally monitored and can be adjusted in case of a malfunction remotely by an experienced Blue Building technician.

The systems run at a low sound level:

30 - 45 dB during the day

20 - 30 dB during the night

Blue Building only uses energy-efficient machines, which are supplied by a trusted partner of Blue Building. You will not only feel the difference in terms of your well-being, but also see it on your electricity bill.

In the Middle East, several projects have already been equipped with this system, which are operating successfully.

Air Quality in Blue Building Houses

Explanation PM2.5 and PM10 (Particulate matter)

The numbers 10 and 2.5 refer to the µm diameter of the particulate matter.

Particulate matter is microscopic solid or liquid matter suspended in the Earth's atmosphere. They include: Gases, smoke, smog, ash and dust, viruses and bacteria, allergens, mold spores and pollen.

Particulates are the deadliest form of air pollution due to their ability to penetrate deep into the lungs and blood streams unfiltered, causing permanent DNA mutations, heart attacks, and premature death. In 2013, the ESCAPE study involving 312,944 people in nine European countries revealed that there was no safe level of particulates, and that for every increase of 10 μg/m³ in PM10 the lung cancer rate rose 22%.

Some particulates occur naturally, originating from volcanoes, dust storms, forest and grassland fires, living vegetation, and sea spray. Human activities, such as the burning of fossil fuels in vehicles, power plants and various industrial processes, also generate significant amounts of particulates.

Example of a Blue Building Technical Room

from Planning - to Completion